The Application of High Voltage Relays in High Voltage Power Supplies and Testing Systems

To ensure personal safety, high voltage electronic equipment must have a high isolation barrier to isolate the voltage from all exposed metal surfaces. In addition, in the event of a malfunction, the high voltage must be immediately disconnected. This standard also applies to distribution equipment, test fixtures, and test probes, where high voltage must be immediately cut off in the event of a fault. This means that the circuit must be disconnected and grounded. Under such conditions, one set of contacts opens the high voltage circuit, and another set of contacts closes the circuit, and the system is grounded.

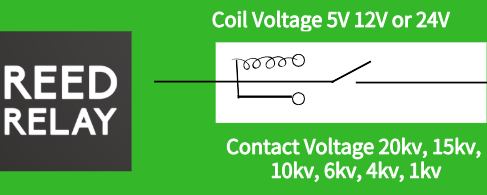

High voltage dry reed relays with hermetically sealed tungsten contacts are the best solution for this type of application. Typically, the switching time for dry reed switches is less than 6 milliseconds, and the breakdown voltage can reach 15kVDC (depending on the type of switch). The contact switch current is 3A, and the maximum load current is 5A. It has multiple contact forms, and can be installed with PCB perforations or high-voltage leads, making it perfect for high voltage environments. Its action time is 3ms, and the release time is 1.5ms, which can quickly respond to control signals. This series of dry reed relays are encapsulated with epoxy resin, and have an insulation resistance of 1012Ω and a leakage distance of more than 32mm, ensuring good reliability.

The HVR series of dry reed relays with voltage resistance of 4KV/5KV/6KV/10KV/15KV/20KV are available.

● Contact forms include 1A/2A/4A/1C/2C/1B

● Switching voltage up to 10KVDC

● Switching current 3A, pulse current 5A/10A/20A

● Insulation resistance above 10T

● Various sizes are available.